AI in Distribution Management:

Harnessing Artificial Intelligence to Optimize Distribution, Enhance Efficiency, and Revolutionize Supply Chain Management for the Future of Logistics

[ Author: Jordan Matthews ]

Nov 19, 2025

No time to read the Must-Read: Listen to the one-minute summary.

Authors

Jordan Matthews

The book “AI in Distribution Management: Harnessing Artificial Intelligence to Optimize Distribution, Enhance Efficiency, and Revolutionize Supply Chain Management for the Future of Logistics” demystifies artificial intelligence for the distribution world. His focus is on showing how AI transforms demand forecasting, warehousing, logistics, customer service, and supplier management into intelligent, data-driven systems.

Quick Summary

This book explains how AI reshapes distribution management by eliminating manual inefficiencies, improving forecasting accuracy, reducing costs, and enabling real-time decision-making across the entire supply chain. It highlights the major pain points in traditional distribution – manual processes, fragmented systems, and poor visibility – and demonstrates how AI, automation, robotics, and predictive analytics address each challenge directly.

Matthews blends conceptual explanations with practical case studies from Amazon, Walmart, UPS, DHL, Blue Yonder, and global retailers, making the book both educational and execution-ready for supply chain leaders.

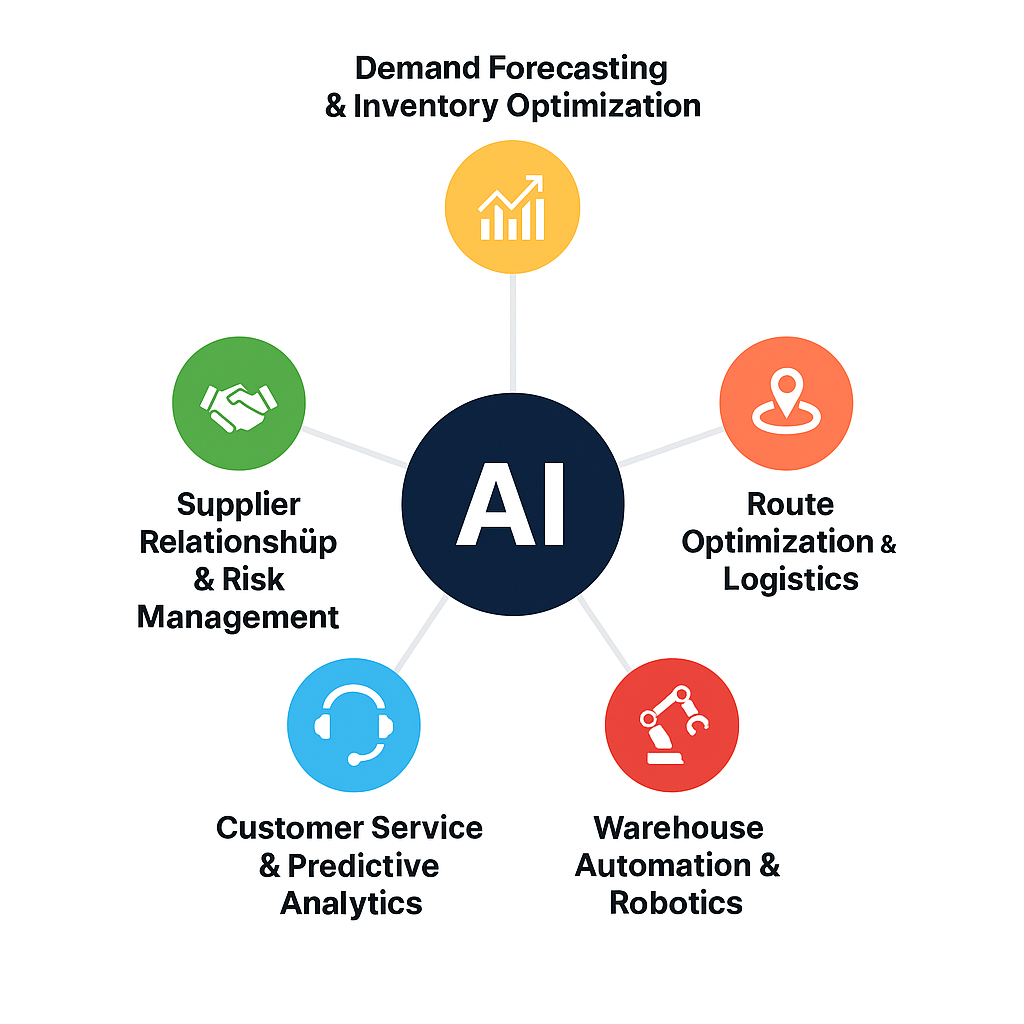

Key Areas Where AI Adds Value in Distribution

1. Demand Forecasting & Inventory Optimization

- Processes vast structured and unstructured data

- Reduces stockouts and surplus

- Enables automated replenishment

- Uses real-time data to dynamically optimize inventory

2. Route Optimization & Logistics

- Real-time traffic, weather, and geospatial insights

- Continuous delivery schedule adjustments

- Improved efficiency, lower fuel spend, and environmental benefits

3. Warehouse Automation & Robotics

- Automated picking, packing, and sorting

- Computer vision for inventory accuracy

- IoT-driven real-time stock monitoring

4. Customer Service & Predictive Analytics

- Chatbots, virtual assistants

- Personalized experiences

- Faster order processing and reduced friction

5. Supplier Relationship & Risk Management

- Performance monitoring

- Early warning signals for disruptions

- Dynamic supplier strategy adjustments

The Need for Integrations in AI-Driven Distribution

| Area | Integrations Needed | Why It Matters |

|---|---|---|

| Demand Forecasting & Inventory | ERP, IoT sensors, multi-channel data (online, in-store, social, weather) | Holistic view of demand, accurate forecasting, better predictive optimization |

| Inventory Tracking & Sorting | Unified inventory + sorting systems, real-time feeds | Automated workflows, accurate data, stronger forecasting |

| Route Optimization | Traffic, weather, geospatial, vehicle/driver, customer/order data | Optimized routes, better delivery windows, reduced delays |

| Real-Time Tracking | Predictive maintenance data, customer tracking portals, ERP + external sources | Peak fleet efficiency, transparency, reduced downtime |

| Customer Service Analytics | Sales, customer, market, operational, social data; cloud systems | Better personalization, contextual insights, real-time responsiveness |

| Supplier Management | Real-time IoT + market data, predictive analytics, dynamic dashboards | Early disruption alerts, improved supplier performance, smarter sourcing |

Key Steps Needed to Implement an AI-Driven Strategy

- Assess Current Operations

Map processes, identify inefficiencies, evaluate data quality, and highlight bottlenecks. - Define Strategic Objectives

Tie AI investments to cost reduction, efficiency, customer experience, and risk mitigation. - Prioritize High-Impact Use Cases

Focus on demand forecasting, inventory optimization, route planning, and supplier risk management. - Calculate ROI

Model savings from lower carrying costs, reduced labor, faster fulfillment, and reduced stockouts. - Create an Implementation Roadmap

Use phased rollouts, integration milestones, budget allocation, and continuous measurement. - Foster Organizational Buy-In

Train teams, manage culture shifts, and communicate success transparently. - Mitigate Risks Early

Address data security, integration complexity, and resistance to technology adoption.

Summary of Common Challenges

- Data Quality Issues

- Difficulty Integrating Multiple Systems (ERP, WMS, TMS, IoT, external data)

- Algorithm Complexity & Continuous Model Training Needs

- Skill Gaps & Lack of AI Expertise

- Employee Resistance & Change Management Problems

- Organizational Silos & Poor Cross-Functional Collaboration

- Legacy System Constraints

- Cybersecurity Risks & Data Privacy Concerns

- Low User Adoption & Cultural Barriers

- Need for Pilot Projects to Reduce Implementation Risk

These challenges recur across multiple chapters and functions – demand planning, warehousing, logistics, customer experience, and supplier management.

Memorable Quote

“Preparing for an AI-driven future in distribution management requires a multifaceted approach that combines strategic planning, robust technological integration, and a commitment to nurturing human talent.”

Key Takeaways for Manufacturers and Distributors

- AI is no longer optional – inefficiencies, manual processes, and data silos directly erode margins.

- Real-time data is the foundation of next-generation distribution.

- Automation and AI improve accuracy, reduce labor costs, and accelerate fulfillment.

- Predictive capabilities help companies avoid disruptions rather than react to them.

- Integration – not just technology – is the defining factor of AI success.

DCKAP Insights

- Distributors should view AI as a unification layer, not just a set of tools.

- ERP modernization and data quality are the core prerequisites before any AI deployment.

- AI brings the most value when applied to high-volume, high-variability activities, such as forecasting, routing, and picking.

- Companies with fragmented systems must prioritize API-driven architectures to unlock scalability.

- AI-driven insights require human augmentation, not replacement-upskilling warehouse and operations teams is essential.

Visual Takeaway

Why This Book Matters Now

AI in Distribution Management is more than a guide – it’s a blueprint for the next decade of industrial competitiveness. Companies that act now will create faster, more resilient, and customer-centric supply chains. Delays will force companies to navigate complexity using outdated tools.

Who Should Read It

The book is written to help supply chain professionals, business leaders, students, and technology enthusiasts understand both the strategic importance and the real-world application of AI across the distribution ecosystem.

About the Curator:

Tamizh Selvan Dinakaran has over 25 years of experience helping businesses grow through digital marketing, particularly in the distribution and manufacturing sectors. He currently leads customer education at DCKAP, where he creates programs designed to help customers succeed in deriving value from DCKAP’s products. Previously, as DCKAP’s Director of Marketing, he focused on increasing brand awareness and generating leads through effective content marketing. Tamizh specializes in B2B content marketing, marketing operations, and customer success.

Read More Book Reviews

ERP Integration made simple for Manufacturers & Distributors.

Transform your commerce journey by creating an integrated experience for employees and customers.