Writing a product spec sheet can be daunting if you do not know how to go about it. After reading this blog you will know exactly how to do it. As unimportant as it may sound, a product specification sheet is pretty much the first step to making a successful product.

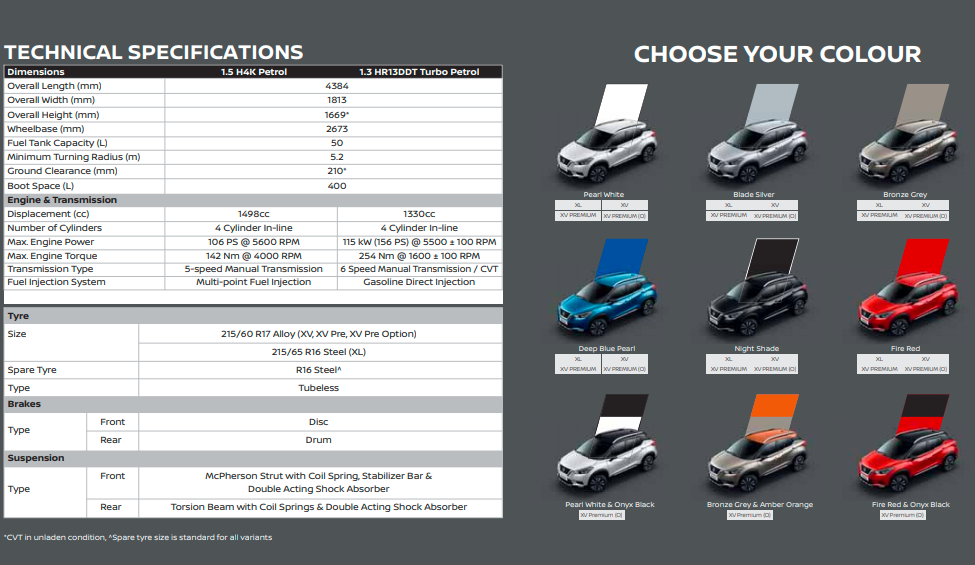

You are sure to have come across product spec sheets in your day-to-day life. For example, if you visit a car showroom the sales representative will hand out a sheet with the comparison of different car models. Even if you do not buy the car the same day, the spec sheet helps you remember the details of each car like its make, motor, steering mechanism, and so on. You will even use that sheet to compare its features with other cars. Below is an image of a car spec sheet available online.

Contents

What is a Product Spec Sheet?

A product spec sheet is a technical document that outlines the features of a product in detail. We see them printed out in sheets or as digital files on the eCommerce websites.

Why are Product Specification sheets important?

Product spec sheets are used to assess the features or components of a product (like the example above), manufacturing information for manufacturing parts (details given to a supplier to get a product made), or as a catalog of information to provide a service or a product.

There a large number of suppliers/customers in the market who make/buy things. If you do not have the required amount of detailing of information to get things done or to sell them, they are likely to move to another seller/manufacturer. A product spec sheet becomes important in this case.

Additional reading- 10 Practical Tips to Write eCommerce Product Descriptions

What to Include in a Product Spec Sheet?

Product spec sheets should be clear and concise. They should provide all the information required to build a product or understand its functionality. They need not contain plain text only. Support them with images, cad illustrations, sketches and so on to give the complete picture of the product expectations. There is no one size fits all approach for writing a spec sheet but here are some details you can include.

- About the product- Its features, Its functions, How it works.

- Parts – What parts are required for its making/ used in making.

- Material– What material(s) is used for the parts.

- Dimensions– Part/product dimensions or Quantities like weight.

- Design – Design details like Cad drawings, Sections, Sketches, Images, Reference models and so on.

- Standard requirements – Quality of materials, quality of testing, usage to name a few.

- Compliance requirements – safety standards, lab testing, document requirements, chemicals/heavy metals restrictions.

- Colour– Pantone colours are a universal language of colour that helps manufacturers/ distributors select the colours for production workflows. A Pantone colour is in the format Pantone-digits-C or Pantone-digits-U. Read more about Pantone colours here.

- Packaging specifications– Label, Type of packaging, Colours.

- Shipping specifications – Container type, Weight, Printing Information, Humidity or Temperature requirements and so on.

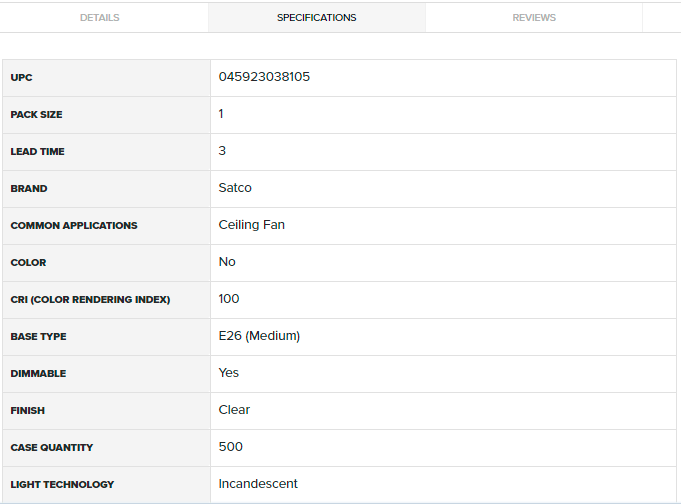

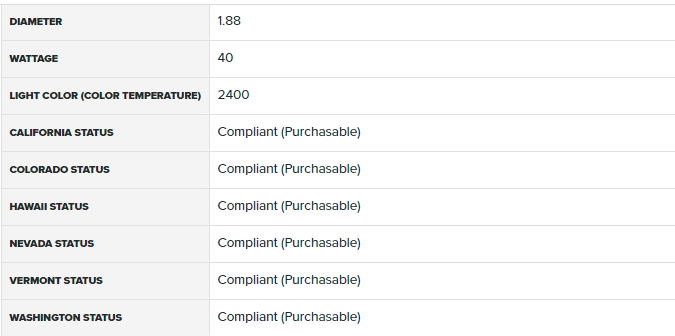

Here’s a spec sheet on Regency Lighting, a commercial lighting distributor in the US that manages 7000 products and their specification sheets using a Product Information Management tool.

How to Make a Spec Sheet?

First things first. Before you start writing a product specification sheet, it is important to research your product. See similar products in the market, order those samples and test them, read reviews from customers about your competition. This will help you understand what the customers expect from products similar to yours. This also helps you cover the loopholes and even cut out unnecessary/unused features.

Now that you have the groundwork done, start working towards your spec sheet.

1. Jot down the most obvious details

A product idea comes to life when it has the right make. To get the right make, a correct product spec sheet is crucial. With the product research details, jot down all the basic details like material, dimensions, make type, quality and so on. This is a base for your further review of the spec sheet.

2. Assume that the reader has no idea about your product

Think of the person who’s going to follow your spec sheet as a layman. Add every little detail but be sure to make the product spec sheet comprehensive and not difficult.

3. Involve all your team members in decision making

Involve the stakeholders and the team to get their ideas and opinions on the make. You can get new information that may prove valuable to the product.

4. Include as much information as you can

Do not leave any detail thinking it is minor. It is better to have additional information than it is to get a faulty make because of one missing detail. Make sure you support the information with sketches, cad drawings, design details, sections and so on. You can use the previously held product research details to your benefit.

Pro tip– Read specification sheets of similar products on regular basis to get a hang of things and be sure not to miss a single detail.

5. Prioritize requirements

The final product model is dependent on just more than your product idea. Things like manufacturing constraints, cost, legal and safety standards come into play when you go about making a product. Thus it is very important to prioritize what is important to you to get the best product.

6. Test It

Make a product prototype with the final specifications and test it for usage, tolerance, features and benefits. Even better ask a team to use the prototypes and get their feedback on what was useful, what wasn’t. You will also get an unbiased opinion on what could be improved. Check for the points where the users are getting stuck at.

7. Do the Final Check

After the testing phase, do a final review. Keep all the technical details and make sure you use simple English for the description. Spec sheets are usually created in spreadsheets, but they have to be sent to the supplier or customer in non-editable formats like PDF. This helps to retain the originality of the document.

Conclusion

Product Specification Sheets are super important.

- They keep the suppliers informed well of your expectations, who otherwise tend to cut down costs for non-specified requirements.

- They help buyers understand and compare if your product is the best fit for them.

- They help you establish your credibility as a technically sound business, especially in the B2B space.

Are you ready to write one for that product idea that’s been around for quite some time now?