Proper warehouse management makes all the difference between swiftly and reliably delivering client orders efficiently and losing customers to delayed shipments and increased costs.

The processes involved in managing a warehouse’s daily operations are collectively referred to as warehouse management. Broadly speaking, this entails receiving and setting up:

- Warehouse space

- Planning labor

- Maintaining and automating inventory

- Completing orders

Warehouse management seeks to streamline and integrate the above in a way that boosts output and contains expenses.

Here’s all you need to know about tech that can help things further, via a warehouse management system, starting with top systems preferred today:

Contents

5 Top Warehouse Management Systems

NetSuite

NetSuite is an eCommerce inventory management program with integrated eCommerce marketing features.

It is an all-in-one ERP system that is cloud-based.

With NetSuite, you can handle payroll, cash flow, finance, and inventory on one platform.

SuiteCommerce is one of the strong tools included in the platform.

This program is excellent for managing any size eCommerce company.

A free trial of the NetSuite software is available.

SphereWMS

The SphereWMS system is intended for precise inventory tracking in warehouses.

It offers a dashboard where you can see information about incoming, outgoing, and inventory.

You will be able to see and manage every aspect of your warehouse operations thanks to this.

Real-time reports and web presence are also provided.

The big platforms Amazon, Blue Cherry, ClickFunnels, and BigCommerce are all integrated with Sphere.

Additionally, it is appropriate for both big and small warehouse operations.

Descartes

Direct-to-consumer companies and fast-growing web businesses are familiar with Descartes.

Descartes excels at keeping an accurate inventory.

It does this by providing simple, real-time access to data from anywhere, at any time, using an Android application.

A customizable dashboard is also included to help you match your team with the objectives of your company.

It’s a solid product overall for both small and large eCommerce warehouses.

Ordoro

Ordoro is a one-stop shop created for expanding merchants.

It can manage dropshipping and organize your operations for fulfilling orders.

Additionally, it simplifies omnichannel inventory management and bulk shipping labels.

For your products, the system event generates custom packing lists and shipping labels.

The best part is that these actions take only a few clicks to complete.

It also allows you to keep order in your orders as soon as you load products into the system.

In general, it’s a wise decision for expanding firms.

Manhattan Associates

Manhattan Associates operates an automated warehouse shipping system.

Deep supply chain and warehouse management services are provided.

Point of sale, store fulfillment, clienteling, and corporate inventory fulfillment are all included.

Advanced software in the product connects with significant ERP systems.

Among other systems, they consist of SAP S/4HANA and Microsoft D365.

In general, the omnichannel, grocery, food, retail, and beverage industries benefit from it.

What is a Warehouse Management System?

A warehouse management system (WMS) is software designed to make managing a warehouse less complicated. A WMS can facilitate the optimization of every aspect of warehouse management.

Key Warehouse Management Processes

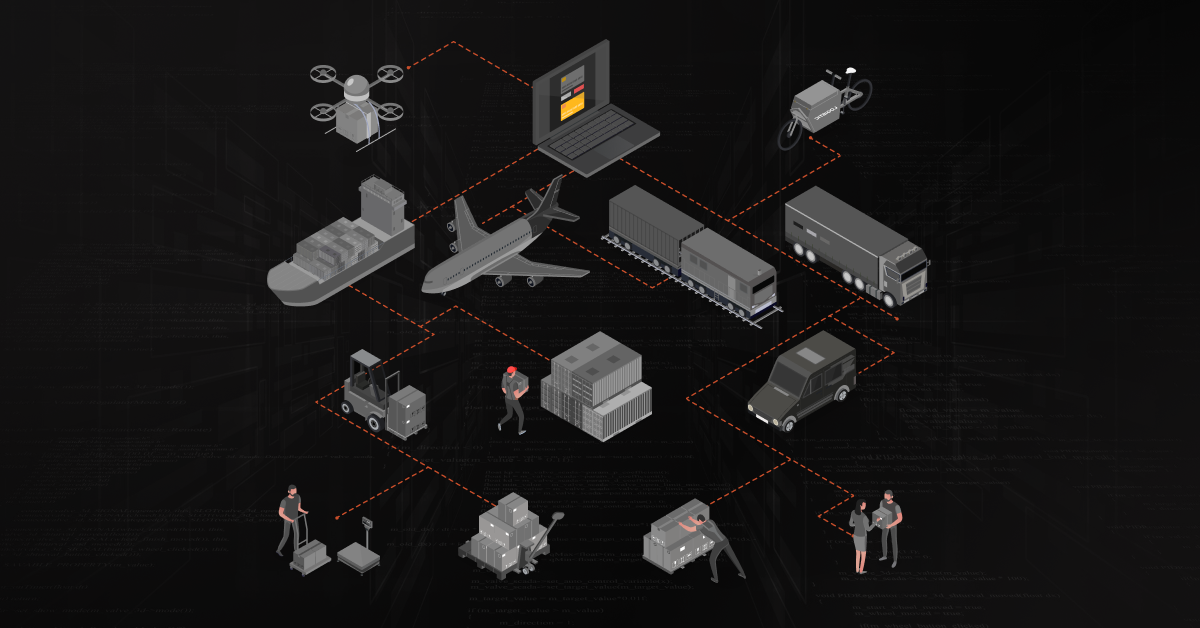

Warehouses play a crucial role in manufacturing and supply chain operations. They house all of the necessary materials created during such processes–from raw materials to completed products.

There are six essential procedures in warehouse management: whether software is used or not. Every process must be tuned for the warehouse operation to function like a well-oiled machine because the effectiveness of one procedure affects the effectiveness of the next.

1. Receiving

Sign in and record any arriving items. Make sure you are receiving the appropriate quantity, in the appropriate quality, and at the appropriate time.

2. Put-away

Transfer the products from the receiving dock to the proper storage areas.

3. Storage

To facilitate quick and precise selection, keep inventory safe and organize it rationally.

4. Picking

Gather the supplies required to complete the sales orders.

5. Packing

Set the chosen items up for shipping. They must be securely packaged in the appropriate containers with a precise packing slip.

6. Shipping

Send out the orders for fulfillment, ensuring that consumers receive their products on schedule.

What Does A Warehouse Management System Do?

A warehouse management system (WMS) is used to ensure that supplies and goods are transported through warehouses efficiently.

Inventory monitoring, picking, receiving, and putaway are just a few of the many tasks a WMS performs to make these movements possible.

Use a warehouse management system for:

Warehouse Layout

Streamlines operations and maximizes storage space, pointing towards where inventory can be positioned where it makes the most sense.

Inventory Tracking

Inventory is monitored using barcode scanners and Radio-Frequency Identification (RFID) for easier tracking.

Employee Performance

The performance of the staff is monitored, and levels that are above or below expectations are documented.

Selection, Packaging, And Shipping

Ensure that the right product is chosen, packaged carefully, and delivered on schedule to the right consumer.

Dock and Yard Management

Help delivery personnel choose the ideal spot to unload their cargo. Streamline inbound and outgoing operations.

Reporting

Managers are given crucial information about the supply chain process to help strategize better.

9 Ways A Warehouse Management System Helps Your Business

Optimize Processes

Allows for more effective operations by streamlining inbound and outbound procedures, automating manual and paper-based procedures like inventory monitoring and labeling, designate more effective warehouse routes, and enhancing the structure of the warehouse.

Better Visibility

They pave the way for increased efficiency and visibility in the warehouse. quicker procedures and better demand forecasting helps supply chain optimization.

Increase Staff Morale

Better employee satisfaction thanks to removing time-consuming and error-prone processes. Improved visibility and more effective task assignments also allow employees to add more value and have more control.

Reduce Spending

Decreased labor expenses due to infrequent human error. Identify products faster, save valuable floor space, and improve inventory visibility.

Make Inventory More Visible

Monitor for ideal stock levels. Use barcodes, serial numbers, and RFID tags, for real-time access to the status of the inventory.

Refine The Management Of Labor

Labor forecasts and KPIs are used to determine when personnel is required as well as how to optimize staffing and shifts.

Increase Security

Increase accountability through an audit trail. Prevent unauthorized access to sensitive information.

Enhance Customer Experience

With fewer errors, quick turnaround times, optimized order status, and enhanced vendor relationships. expect improvements in customer satisfaction.

Continuous Improvement

Data and visibility are useful in detecting problems and making adjustments. For instance, “what if” scenarios can be run by WMS software to see how changes will affect operations.

Managing your eCommerce warehouse

The act of organizing and storing products meant for online sales at a warehouse is referred to as eCommerce warehousing.

Some e-commerce warehouses are controlled and operated by the retailer. Others are under the control of 3PLs and third-party fulfillment companies. Managing activities involved in operating an eCommerce warehouse is as eCommerce warehouse management.

Typical e-commerce warehouse operations include:

- Implementing the necessary safety and security procedures for the storage of merchandise.

- Receiving and storing product as it enters your warehouse for online sales.

- Controlling each SKU’s bin, shelf, and/or pallet positions to get the best possible warehouse slotting.

- Conducting inventory and warehouse audits.

- Analyzed inventory reports and kept track of stock levels.

What Happens Without eCommerce Warehouse Management

It doesn’t matter if you rent storage space or keep inventory in your own. If you don’t deploy effective warehouse management, things may go horribly wrong very quickly.

Without it, the following may occur:

More Instances of Inventory Being Misplaced

Every variation on your website has a storage location that is tracked by an eCommerce warehouse management system. The stock might be lost without this technology, specifically as your company and product line expand.

Errors In Shipping Orders

If you don’t keep a close eye on your inventory, you can unintentionally send your consumers the wrong products. This may discourage repeat business from both new and devoted clients.

Warehouse management can help your bottom line, thanks to its positive impact on customer experience.

Storage Is Exhausted

Many small businesses struggle to find enough room to keep products at home.

Stock-Outs Or Excessive Inventory Purchases

Using planned e-commerce warehouse management, you can estimate the ideal amount of goods to keep on hand. Stock-outs and missing out on prospective online sales are both risks associated with having too little inventory. If you have an excessive amount of inventory, you run the risk of having unsalable goods on hand.

Difference Between ERP And Warehouse Management Systems

WMS and ERP are two distinct software programs created for various uses.

The purpose of a warehouse management system is to streamline daily operations, increase inventory accuracy, and offer real-time insight into warehouse activity.

ERP software is a collection of business management tools that includes a variety of modules to handle every aspect of organization management. The majority of ERP systems provide a module for a warehouse management system, although the functions offered by each one vary.

Benefits of WMS Integrated With ERP?

There are several new technologies that are making warehouses more productive. However, they are limited in what they can accomplish without being integrated with other areas of your company.

A WMS integrated with your ERP system will offer distinct advantages, including:

Increased Collaboration And Exposure.

The exposure of the organization as a whole is increased by having all data and workflows organized and shared in one system.

Additionally, it enhances coordination and collaboration and combines production and warehousing activities with key company operations like finance, customer service, and logistics.

Eliminating Redundant Processes

Since data is kept in a centralized manner, there is no need for manual intervention and the errors that result from data having to be entered again.

Improved Decision-Making

Informed judgments are made easier with the support of real-time information from the warehouse about inventory status, client orders, and organizational schedules and plans.

Improved Customer Satisfaction And Sales

Delivers to the sales team the details on what is in stock and the required lead times. With access to real-time data about consumer orders and delivery schedules, commitments can be met well.

Quicker Billing

Invoices can be sent more quickly when shipment information is processed right away and delivered to accounting.

Keep Track of Output

Managers can make sure that work continues to move along and monitor how well employees are functioning with the help of immediate notice regarding where people are with their jobs.

How To Choose The Right Warehouse Management System?

Now you’re up to speed with everything you need to know about Warehouse Management Systems. We’ll leave you now with some important factors to consider on the next leg of your WMS journey, i.e., choosing the best WMS for your company:

Budget/ROI

To assist you in setting your budget, consider the benefits a warehouse management system would provide. Your purchase should yield the following benefits for you:

- Enhanced procedures and effectiveness (doing more with fewer resources).

- Lowered expenses as a result of improved inventory control and efficiency advantages.

- Improved customer service leads to more revenue and customer loyalty.

- Improved decision-making due to less rework and increased accuracy.

- Improved traceability and visibility.

- Higher productivity

- Better use of available space

Functionality

Seek systems that can do the tasks that are most crucial for your business. The following are a few necessities you’ll need:

- Monitoring of inventory movement in real-time

- Efficient use of staff, resources, and space

- Increased dispatch, packing and picking precision

- More operational insight

- Modern technologies, such as RFID, serialization, mobility, and barcoding.

Vendors

- Check into the suppliers and products that best fit your requirements and price range.

- Make an information request (RFI).

- Make a short list of the providers and/or solutions you like.

- To learn how their solutions operate, watch demonstrations, presentations, movies, etc.

- Obtain and haggle over price estimates.

- Check your sources.

- Choose your response!